3D Scanning

Why use a 3D Scanner?

- To make an exact copy of an existing item with a 3D printer

- To iterate (slightly modify) an existing design

- To add the scanned item into a digital artwork, animated film, video game, or virtual reality environment

- To create virtual copies of items for preservation purposes

How do 3D scanners work?

They use one of these:

- Photogrammetry: measurements calculated from 20-250+ photographs

- Structured Light: triangulates dimensions using small camera & projector

- LASER Triangulation: LIDAR, determines time it takes for laser to return

- Contact Based: probes the item using physical touch

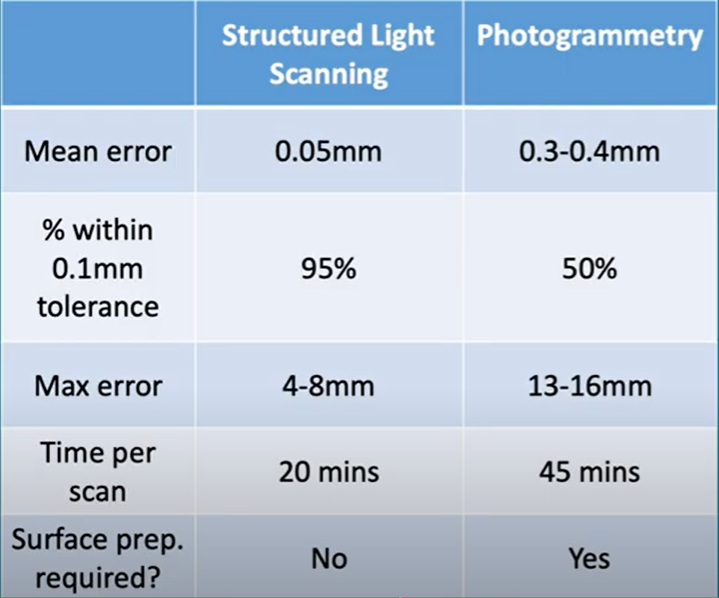

Photogrammetry vs Structured Light (Source)

What type of scanner does the Maker Lab have?

POP 2 Scanner

POP 2 Scanner

- Structured light 3D scanning technology

- .05mm precision, can scan in color

- 20 mm ×20 mm × 20 mm minimum scan volume

- Uses Revopoint software

- Outputs in PLY, OBJ, & STL

Scanning Tips

- Small scans should generally be the size of your fist

- POP 2 has an easier time scanning lighter objects

- You can scan people, animals, and plants using the scanner

- It is very difficult for the scanner to scan flat objects